Design and Efficiency

After the successful exhibition in Pordenone, Gammaplast agenda for the 2016 fairs continues towards Parma. From 17th to 19th March, the Company exhibits at MECSPE with a 3-days event in the name of efficiency, integration of services and process innovation.

Gammaplast takes this opportunity to state itself on the market with a new visual identity and, this is not a play on words, with a new vision: it exposes in fact one of the technologies where the Company foresees one of its own direction of growth and development.

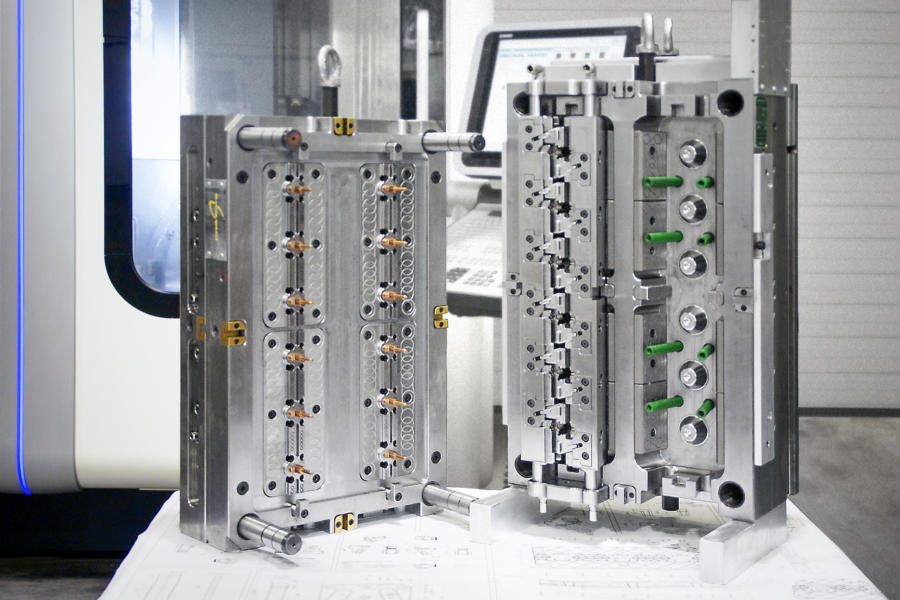

An Allrounder 470 E 1000-290 of the EDRIVE series will be equipped with a mould designed and built by Gammaplast, which has been kindly disposed by the final client Ferramenta Livenza.

The equipment, which produces one of the components of the “invisible” support for shelves Secret SL25, renowned for its high added value in the technical field.

The part is characterized by the complexity of an elegant design that, together with the other components, gives birth to a finished product that has a function of use simple and very versatile. These factors of innovation arise in a company of the Liventino District and reach a European resonance; the Secret was in fact awarded for two consecutive years on the German market: in 2013 with an Interzum Award and in 2014 with a Germany Design Award.

Gammaplast is proud, as a manufacturer, for its contribution to a process that meets either the technical or the quality standard, to an equipment whose is asked to meet goals of high productivity. The constructive peculiarities of this mould allow, in this circumstance, the appreciation of some benefits of the electrical transformation that, by definition, is oriented to guarantee at the same time performance and efficiency.

According to many professionals, this technology satisfies mainly those applications belonging to packaging or medical sectors, thanks to the high acceleration and speeds of the clamping unit. This indisputable benefit is a matter of careful consideration within the technical item field, where the constructive requirements of the equipment in part bind, but with good reason, to the cycle times. The Support Secret SL25 is an application already “fast”, which in fact requires a balance between the highly optimized mechanical design and the transformation process, therefor an expert eye will appreciate how the electrical transformation contributes with a margin of manoeuvre, especially in terms of precision and control of the movable parts.

The Arburg electric machine is in fact equipped with actuators with direct coupling without backlash, which guarantee highly dynamic and precise movements, constant over time thanks to temperature control over liquids of engines and transmission systems.

Repeatability and reliability have a primary importance for an apparatus that, as in this case, has complex movable parts. Opening and closing phases involve four lifters in the fixed part, which implement 2 movements for each of the 12 cavities of the mould.

The roller satellites screw of new conception, the heart of the transmission system of the injection unit, also allows high accelerations and decelerations and great precision of movement, determinants in the injection phase of very technical parts, which are commonly problematic. In support of an injection that has to be precise and controlled in every variable, in this application intervenes the temperature control of the hot runners signed Thermoplay, by means of a control at 12 and 6 zones.

“Come to meet us, we are pleased to serve your projects”

© Copyright of Gammaplast s.r.l.